GCL Vertical Casepacker (gravity)

The GCL vertical casepacker (gravity) is especially designed to pack in a compact way bags vertically into a "display" cases.

Request for quoteFunctional description

GCL vertical packing

The GCL casepacker places pillow, block bottom and doy style bags in an upright position into “display” cases. The bags are fed in original position lying flat on the infeed conveyor. A race track collects the bags and put them in an upright position until a complete row has been formed. One or more rows of bags are possible.

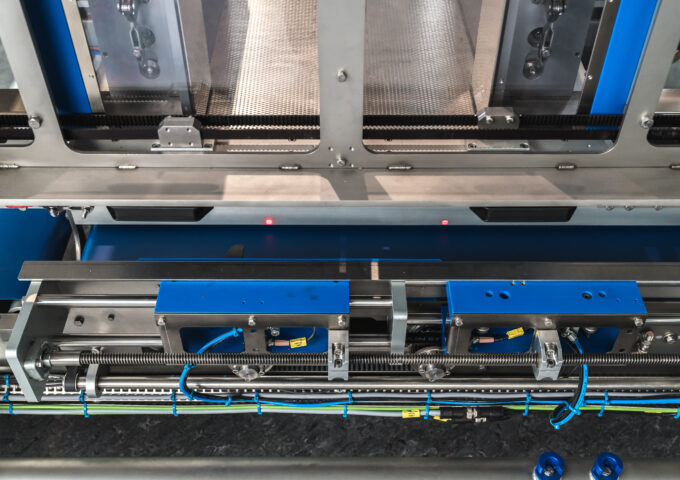

Product pusher

The whole row is then transported besides the discharge position. Pushed out of the racetrack onto the bomb doors. Once the bags (single or multiple rows) are in discharge position, the doors are pulled away to the side creating an opening and drop the bags into the case.

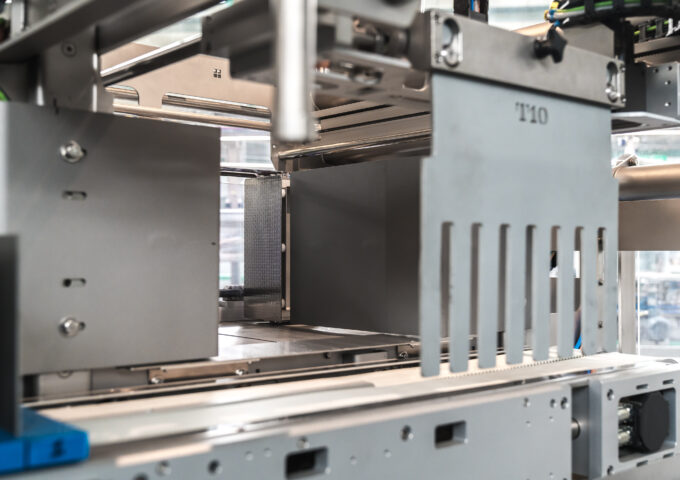

Case change unit

The case change unit is equiped with a vibriating system and is menu controlled. Enabling easy changeovers between different case dimensions.

Hygienic designed frame

The GCL has a hygienically designed machine frame. F.e. use of round tubes in the frame construction, and cables have been concealed in the frame where possible. Great attention has been paid to easy cleaning of the machine.

Features

What makes the GCL unique?

- Userfriendly, wizard for automatic programming, menu controlled and toolless adjusting via menu.

- up to140 bags/minute possible by using simple technology.

- Good accessibility for service purposes.

- Standard executed with remote access.

- Expandable with many options for custom made delivery.

- Hygienic design, using stainless steel and aluminium components.

- Small footprint.

Technical properties

Product data GCL Vertical Casepacker (gravity)

| General dimensions | 3.200mm x 2.000mmx 2.400mm |

| Product infeed height | 900mm |

| Case in-and outfeed height | 450mm |

| Electrical | 3phase 400V + N + PE 50Hz 5kW 16A |

| Compressed air | 350 Nl/min, 6bar |

| Weight | 1.100kg |

| Case / crate dimensions | Max. 600 x 400 x 550mm (open) Min. 185 x 110 x 110mm (closed) |

| Capacity | up to 140 products/min or 20 cases. |